| Business Price: | View Latest Price ₹1.00 + GST |

| Final Price: | ₹1.00 (incl. GST) |

| Stock Availability: | Stocked On-demand |

Product Specification

| ITEM CODE | BO-TECHNO-0 |

|---|---|

| ITEM NAME | Black Oxide |

| Thickness | 0-30μm / 0-1181μin |

| Applicable materials | Carbon Steel, Stainless Steel, Copper-Based Alloys |

| Colors | Steel, Stainless Steel, Copper |

| Surface preparation | As machined (Ra 3.2μm / Ra 126μin) |

| Brand | TECHNO |

| COO | Made in BHARAT (IN) |

| Finish | Chemical Conversion Coating (Black Oxide / Blackening) |

Product Description

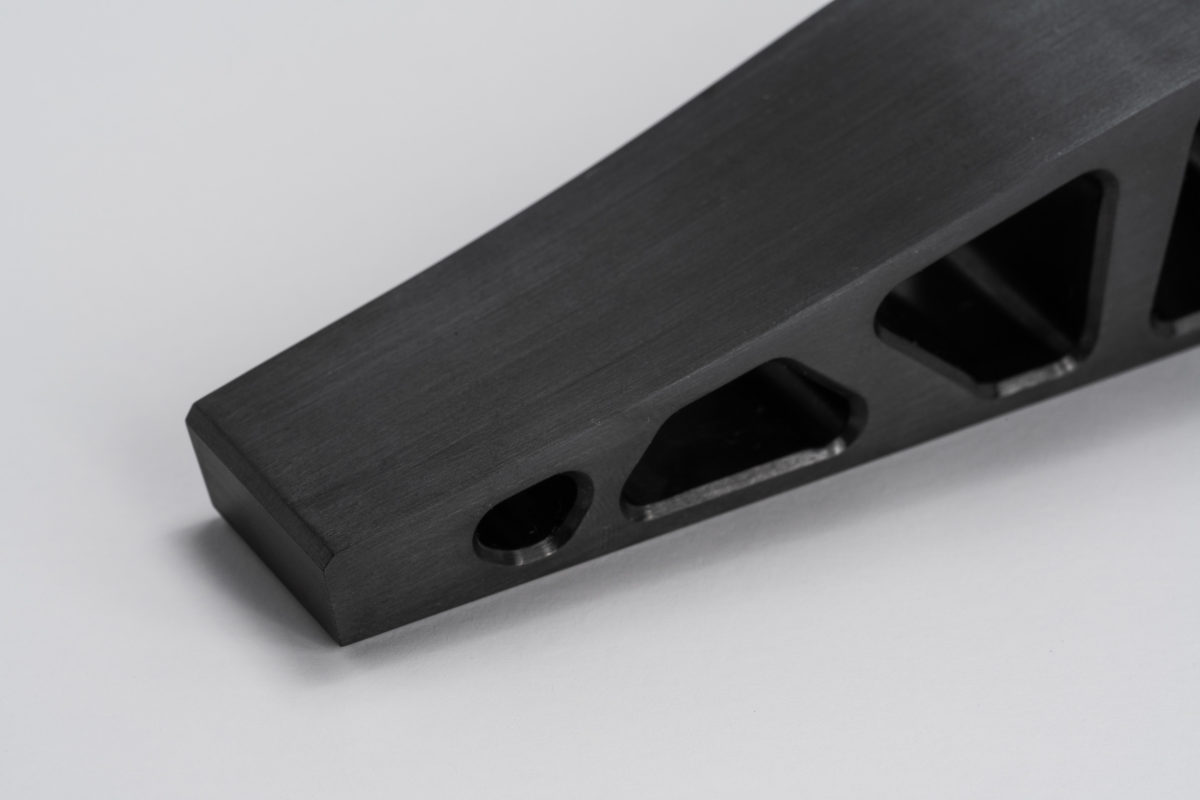

TECHNO CNC proudly offers Black Oxide Surface Treatment Services, providing a classic black finish that enhances appearance, improves corrosion resistance, and increases wear life without altering the critical dimensions of your parts. Black oxide is a chemical conversion coating created by a reaction between the metal and an oxidizing salt solution at controlled temperatures, offering low-cost protection combined with a professional aesthetic.

Our Black Oxide Process is ideal for ferrous and non-ferrous metals, especially steel, stainless steel, and copper alloys. With the option of oil or wax post-treatments, parts gain superior corrosion resistance while maintaining a uniform black appearance, making it perfect for industrial, automotive, tooling, and defense applications.

Enhance the longevity, functionality, and visual appeal of your components with TECHNO CNC’s expert black oxide finishing solutions, designed for both aesthetic refinement and operational excellence.

Features: Minimal change to surface, abrasion resistant, low cost

Appearance: Uniform dark black. A small amount of oil and/or chemical residue may remain on your parts

The Black Oxide Finish offered by TECHNO CNC is a chemical conversion coating process used to provide a durable, corrosion-resistant, and aesthetically pleasing black surface on ferrous metals and select copper-based alloys. This finish is widely recognized for its minimal dimensional impact, making it ideal for tight-tolerance machined parts where surface enhancement is required without altering component geometry.

Post-treated with protective oils or waxes, the black oxide layer offers increased resistance to humidity, oxidation, and light abrasion, making it perfect for military, industrial, and tooling applications. In addition to its protective function, the matte black appearance provides non-reflective properties, aiding in light control and aesthetic appeal.

Additional Information

| COMPATIBLE WITH | Corrosion Protection, Cosmetic Enhancement, Dimensional Stability |

|---|---|

| MOQ | 1 Part or Bulk Orders Accepted |

| PACKAGE | Depends on Component Size |

| AVAILABILITY | On-Demand; Custom Scheduling Available |

| EST. SHIP | Fast Global Delivery with Secure Logistics |

| UPDATE | 24/06/2025 J |

| Uses | Low light reflection, limited corrosion protection, Mechanical Parts, Firearms, Tools, Military Equipment, Precision Optics |

+91-97277 26697

+91-97277 26697