| Business Price: | View Latest Price ₹1.00 + GST $1 | €1 |

| Final Price: | ₹1.00 (incl. GST) |

| Stock Availability: | Stocked On-demand |

Product Specification

| General Cost Saving Machining Tips | Machining can be an expensive process, but it doesn’t have to be. You might not realize there are simple ways to reduce manufacturing cost. In fact, some of the smallest adjustments in your design will not only save you money but will get the job done faster. |

|---|---|

| MORE IS LESS | Ordering in bulk allows you to amortize setup cost between more parts, significantly reducing the cost per part. |

| COMMUNICATE WITH YOUR MACHINIST | Be as thorough as possible in your instructions to the machinist. Include all necessary details about your part such as intended functionality, tolerances, finishes, etc. A better understanding of your particular needs could lead to a more efficient manufacturing process, resulting in lower costs. |

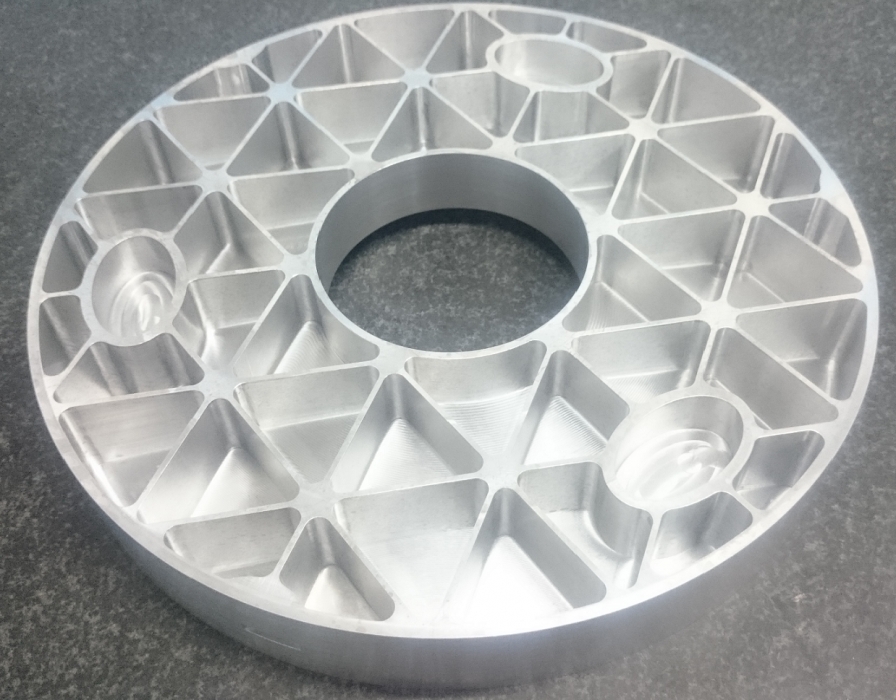

| LEVERAGE 2D DESIGNS | 2D parts are typically less costly to manufacture than 3D parts. When possible, avoid including three dimensional features which often require added machining processes. |

| DEBURR VS CHAMFERING | Deburring parts (often included at no charge) is often a more economical alternative to chamfering which requires more advanced equipment and hence cost. |

| PART SIZE | Making parts smaller helps you save in two ways because small parts: 1. Require less material 2. Can often be nested in greater quantity |

| ELIMINATE UNNECESSARY FEATURES | Unnecessary finishes and irregular shapes that don’t affect functionality increase cost without providing additional value. |

| USE THRU HOLES | Use thru-holes with machine screws and nuts instead of threaded holes in your designs. This saves the manufacturing step of tapping. |

| STICK TO STANDARD SIZES | Use standard thread sizes. Uncommon thread sizes may require your machine shop to purchase a tap they don’t have which raises the price. When in doubt, ask your machine shop whether they have the size you need. |

| CHOOSE YOUR MATERIAL WISELY | Choose the softest and lowest cost applicable material for your parts. Soft, common metals such as aluminum are easy to machine and don’t stress machinery as much as harder materials. |

| CONSIDER MACHINABILITY | Keep in mind that some materials are lower cost for the raw material but could also take longer to machine costing you more in the end. |

| STAY LOOSE | Minimize use of tight tolerances. Set them as loose as possible. Tight tolerances may call for additional processes and longer machining time. |

| FINISHES / SECONDARY PROCESSES | Minimize the number of finishes. For example, instead of bead blasting followed by powder coat, it is usually sufficient to specify only powder coat. |

Product Description

Looking to cut costs & boost profitability in your manufacturing operations? TECHNO CNC presents 12 Cost-Saving Tips for Manufacturing, a must-read guide for manufacturers, factory managers, and production planners.

This comprehensive resource covers practical strategies to reduce waste, optimize resources, improve energy efficiency, enhance automation, and streamline supply chain management. Whether you're in CNC machining, metal fabrication, automotive, or general manufacturing, these insights will help you reduce expenses without compromising quality.

Additional Information

| USES | As Multi Applications. Manufacturing cost reduction, production efficiency, waste minimization |

|---|---|

| MOQ | 1 PIECE or No MOQ |

| PACKAGE | Corrugated Box or As per Custom Need |

| AVAILABILITY | As Per Client Needs |

| EST. SHIP | SHIP IN 24-48 HOURS |

| UPDATE | 01/03/2025 J |

+91-97277 26697

+91-97277 26697