Product Specification

| Density | 0.283 lbs/in^3 |

|---|---|

| Melting Point | 2775 F |

| Temperature Range | -100 to +800 F |

| Hardness | 126 |

| Hardness Scale | Brinell |

| Yield Strength | 54 KSI |

| Shear Strength | 11.6 KSI |

| Tensile Strength | 64 KSI |

| Thermal Conductivity | 30 Btu/hr-ft-F |

| Thermal Diffusivity | 1.09 sq in/min |

| Modulus of Elasticity | 29.7 x10^6 lb/sq in |

| Weldability | Good |

Product Description

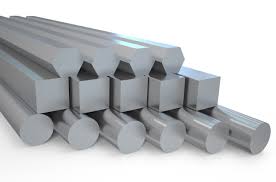

Steel 1008 and 1018 Cold Rolled are low carbon mild steels widely used in CNC machining due to their excellent weldability, formability, and dimensional accuracy. Cold rolling enhances their surface finish, strength, and tolerance control—making these grades ideal for precision components and structural parts.

Steel 1008 is known for its superior formability and is often used in stamping and drawing applications. Steel 1018, on the other hand, offers improved machinability, higher strength, and cleaner finishes, making it a favorite for shafts, pins, and fasteners.

Both grades are cost-effective, versatile, and easy to machine, making them popular in automotive, construction, and general industrial applications.

Note: this material comes in a limited set of thicknesses.

Additional Information

| USES | General-purpose machining, shafts, spindles, pins, rods, sprockets. |

|---|---|

| UPDATE | 07/06/2025 J |

+91-97277 26697

+91-97277 26697