| Business Price: | View Latest Price ₹2200.00 + GST 2200.00++ |

| Final Price: | ₹2596.00 (incl. GST) |

| Stock Availability: | Stocked On-demand |

Product Specification

| ITEM CODE | G652.11 |

|---|---|

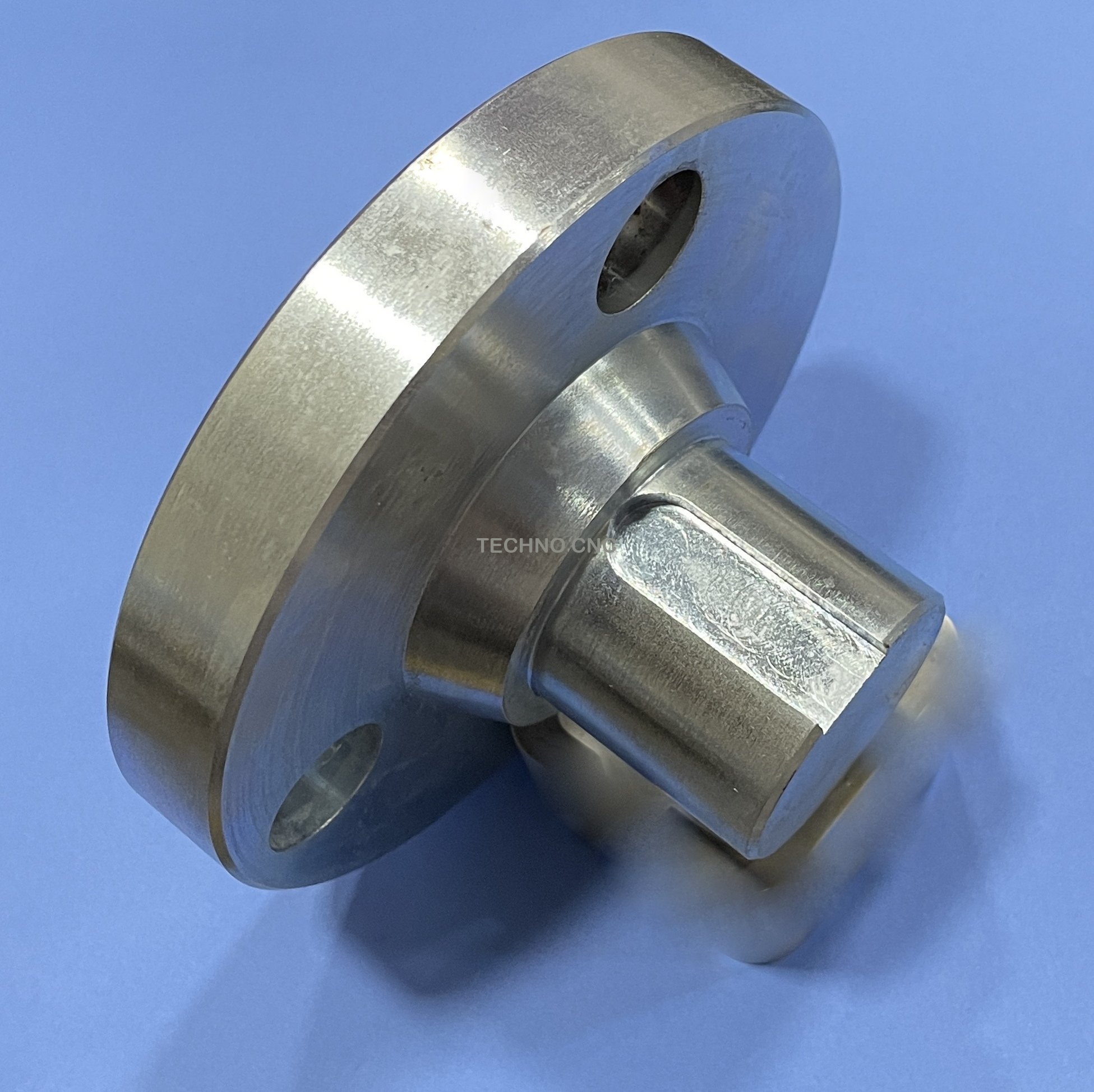

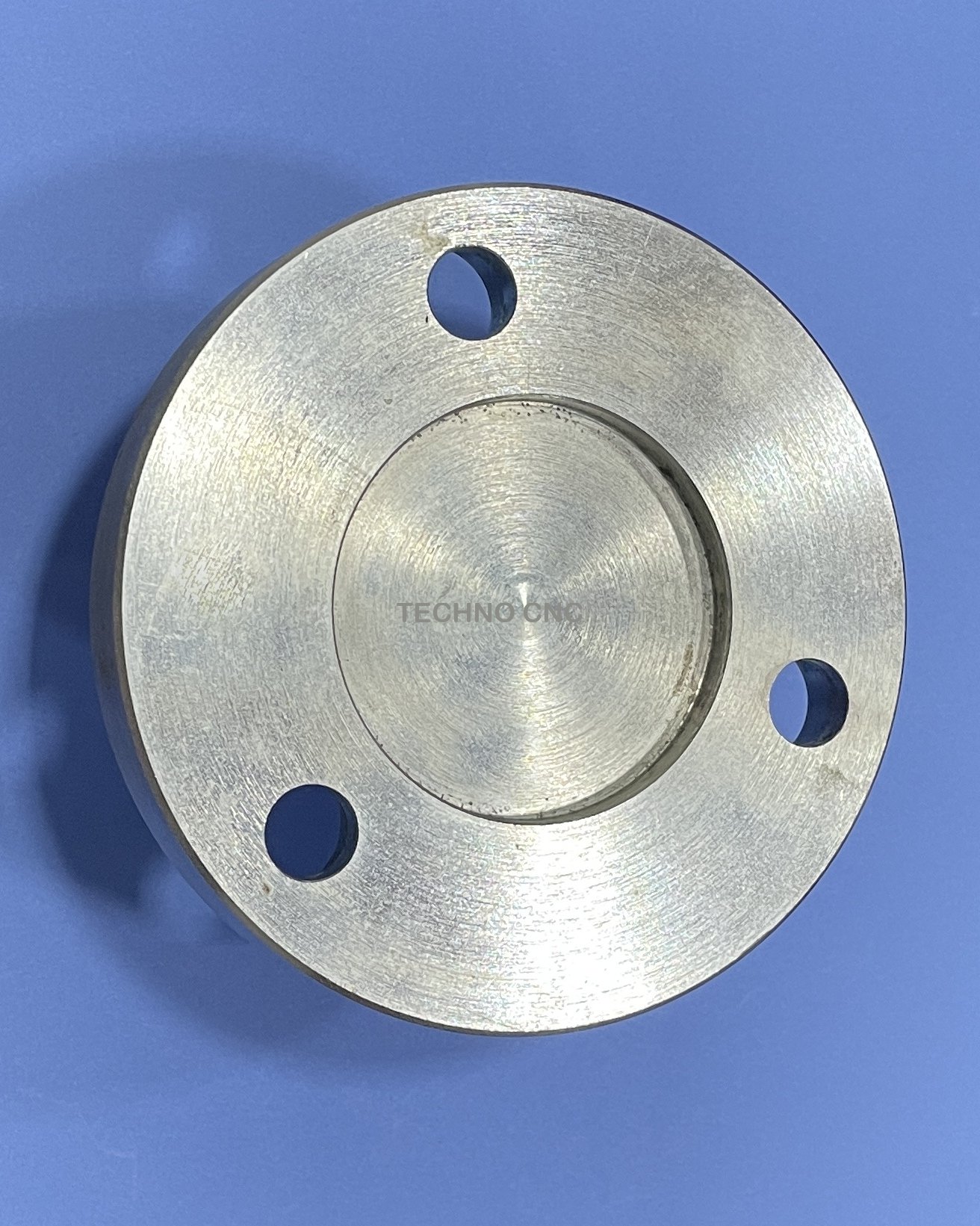

| ITEM NAME | SHAFT FOR COUPLING MOUNTING |

| DIMENSIONS | Custom as per design |

| ITEM WEIGHT | 1.960 KG |

| MATERIAL | As per customer application (EN-Series / SS / Alloy Steel) |

| FINISH | ZINC OR BLACKOXIDE |

| BRAND | TECHNO |

| COO | MADE IN BHARAT (IN) |

Product Description

TECHNO CNC presents the Shaft for Coupling Mounting, a high-precision CNC-machined drive shaft engineered to deliver exceptional alignment stability, torque transfer, and mechanical robustness in demanding industrial systems. Designed to integrate seamlessly with a wide range of couplings, this shaft ensures superior concentricity, minimal vibration, and long-term operational reliability.

Manufactured using advanced multi-axis CNC processes, the shaft is crafted from premium alloy or stainless steels, ensuring durability, wear resistance, and stability under continuous high-load conditions. With options for keyways, splines, threaded sections, and custom end profiles, the product is tailored to meet both standard and specialized OEM applications.

Whether used in automation machinery, high-speed power transmission assemblies, industrial pumps, compressors, or servo systems, this coupling mounting shaft provides unmatched precision and performance across the full range of dynamic loads.

Key Features

High-Precision CNC Machining ensuring superior dimensional accuracy and perfect coupling alignment.

Excellent Torque Transfer Capability ideal for industrial drive systems.

Tight-Tolerance Concentricity minimizes vibration and improves overall system efficiency.

Available with Keyway, Splines & Thread Profiles for direct mounting compatibility.

Heat-Treated for Strength & Wear Resistance based on application requirements.

High Surface Finish Quality resulting in lower friction and extended bearing/coupling life.

Material Flexibility including alloy steels and stainless steels for performance-specific needs.

Fully Customizable Geometry to match specific OEM coupling configurations.

Additional Information

| USES | LAMINATOR MACHINE |

|---|---|

| MOQ | Custom or Bulk Orders Accepted |

| PACKAGING | As per Item Geometry & Quantity |

| AVAILABILITY | Ready-to-Ship or Made-to-Order |

| EST. SHIP | Fast Global Delivery with Secure Logistics |

| UPDATE | 30/11/2025 J |

+91-97277 26697

+91-97277 26697

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)