| Business Price: | View Latest Price ₹50.00 + GST |

| Final Price: | ₹59.00 (incl. GST) |

| Stock Availability: | Stocked On-demand |

Product Specification

| ITEM NAME | Multi-Directional Ball Transfer Units for Material Handling |

|---|---|

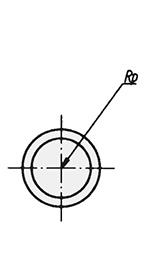

| DIMENSIONS | OD 15 mm, Over Length 14 mm Ball Die 8 mm |

| ITEM WEIGHT | Zinc-Plated Steel / Stainless Steel / Nylon Composite |

| MATERIAL | Hardened Steel / Stainless Steel |

| BRAND | TECHNO |

| Country of Origin | Made in BHARAT (IN) |

Product Description

Multi-Directional Ball Transfer Units from TECHNO CNC are robust, high-performance components engineered to facilitate smooth, omnidirectional movement of materials on conveyors, assembly lines, and handling tables. These precision-machined transfer units consist of a large load-bearing ball supported by smaller internal ball bearings, allowing effortless rotation and direction change.

Designed for maximum reliability and load-bearing capacity, these units are ideal for both light and heavy-duty applications. They are manufactured using premium-grade stainless steel or zinc-plated materials to ensure longevity, corrosion resistance, and consistent rolling performance, even in demanding industrial environments.

Whether installed on cargo handling systems, machinery feed points, or logistics conveyors, these ball transfer units enable fast and flexible movement with reduced handling effort.

Ball Transfer Units Plastic 15mmPUSH FIT SPRING PLUNGER 15mm

Ball Plungers for Precise Vacuum Positioning

A ball plunger is a mechanical component commonly used in slide mechanisms and other applications to provide precise positioning and control. In the context of a vacuum system, it can be used to precisely control the movement and position of objects within a vacuum chamber.

Here's how a ball plunger can be used in a vacuum system for positioning:

1. Components of a Ball Plunger: A typical ball plunger consists of a body with a threaded or unthreaded shaft, a spring, and a ball at the end of the shaft. The spring pushes the ball outward, creating a contact point for positioning.

2. Vacuum Compatibility: It's crucial to select a ball plunger that is compatible with the vacuum environment. This means the materials used in the plunger should not outgas or react with the vacuum, and the plunger should maintain its functionality in a vacuum environment.

3. Mounting and Positioning: Install the ball plunger at the desired location within the vacuum chamber. It can be mounted on a bracket or fixture. When the plunger's ball contacts an object, it provides precise positioning control due to the spring's resistance.

4. Adjustability: Depending on the specific application and requirements, you may need to adjust the plunger's position. Most ball plungers come with adjustable mechanisms to set the extension length or force applied.

5. Sensors and Control: In advanced applications, sensors can be added to the ball plunger setup to provide feedback on the position. This feedback can be used to control the positioning automatically, ensuring high precision.

6. Maintenance: Regular maintenance and cleaning may be required to ensure the smooth operation of the ball plunger within the vacuum environment.

Keep in mind that when operating in a vacuum, you'll need to consider factors such as thermal expansion and contraction, as well as the potential for contamination or wear due to the absence of air. Selecting the right materials and components that are compatible with vacuum conditions is essential for the successful operation of your positioning system.

Bearings

Here at Bearingboys, we offer a broad range of ball transfer units, including light, medium, and heavy-duty options. Available in either chrome or stainless steel, ball transfer units ensure loads can be moved smoothly and with minimal effort in multiple directions. They are typically used face up so that goods may be moved across them, but are also used face-down in some circumstances. We offer a number of different types of fitting, including push fit, flange mounted, Saturn type, and internal thread options. Choose the most appropriate type at the relevant tolerance, and we can then also offer a product to fit your price range.

Additional Information

| Uses | Omni-Directional Material Transfer in Industrial Systems |

|---|---|

| MOQ | As per Specification |

| PACKAGE | Based on Unit Size and Quantity Ordered |

| AVAILABILITY | Ready Stock & Made-to-Order Available |

| EST. SHIP | Fast Global Delivery with Secure Logistics |

| UPDATE | 19/04/2025 J |

+91-97277 26697

+91-97277 26697